One of the most well-known Manufacturers, suppliers, and exporters of Inconel 600 round bars is Shasan Piping Solution. There are many industries that use these Inconel 600 Rods (UNS N06600), including the meat and paper industry, food processing, atomic design, and gas turbine parts. With it, the possibilities are endless. In carbon nitriding procedures, for example, our Alloy 600 rods are also used for brilliant cylinders and roller hearths. It is possible to machine alloy 600 round bars both under strengthened and hot-worked conditions. Up to roughly 1000 degrees Fahrenheit, dry Cl2 cannot penetrate Nickel 600 Round Bars. These Nickel 600 Rods are available at completely cheap prices because we have a truly manageable cost range. The sizes of these products are standard. Other especially made sizes and shapes are welcome, too.

Shasan Piping Solution is one of the most seen exporter, supplier and Manufacturers of Inconel 600 Round Bars. These Inconel 600 Bars (UNS N06600) are used in a lot of usages, for instance, for Crush and paper industry, Food processing care, Nuclear Planning, Gas turbine parts, and anything is possible from that point. Our Alloy 600 Bars are also used for roller hearths and splendid Tubes, for instance, in carbon nitriding processes especially. Alloy 600 Round Bars is machinable in both the hot worked and Stainless conditions. Nickel 600 Round Bars are impenetrable to dry Cl2 to around 1000 Degree F. We have a genuinely conceivable expense range which makes these Nickel 600 Bars open at very much sensible expenses. These things come in standard sizes. Other exceptionally made sizes and shapes are welcome moreover.

An excellent and flexible metal alloy for exhibiting is Inconel 600 round bar. This substance, which is made of nickel and chromium, is resistant to erosion and can withstand high temperatures. This makes it perfect for usage in contemporary applications such as power-age components, valves, process hardware, heat exchangers, and other auto parts where synthetic blockage and temperature are factors. Because of its widespread mechanical strength and durability, it can also be used in atomic reactors. For modern parts in endeavors like aviation, chemical processing, oil refining, and more, Inconel 600 round bar is a strong yet lightweight option.

Round bars made of Inconel 600 and 601 are materials used in several contemporary applications. There are distinct differences between the two alloy kinds even if they have many similarities. The nickel-chromium alloy Inconel 600 has excellent resistance to erosion, is widely formable and weldable, and can withstand temperatures as high as 2000°F. It's interesting to note that Inconel 601 has additional aluminum and chromium at significantly higher amounts for enhanced oxidation resistance at higher temperatures. This alloy's oxidation solidity, strength, durability, and flexibility make it perfect for use in demanding environments. When accuracy is crucial, knowing the differences between Inconel 600 and 601 round bars will help you select the right material for the job.

Specifications:

Standards : EN, DIN, JIS, ASTM, BS, ASME, AISI

Size : 5 mm To 500 mm Dia in

Length : 100 mm To 3000 mm Long & Above

Specifications : ASTM B 166 / SB 166

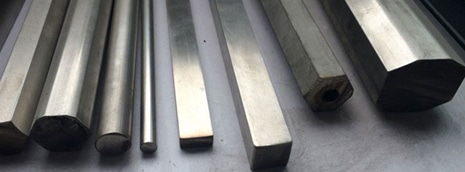

Form : Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wire-mesh, Billet, Ingot, Forging Etc.

Finish : Bright, Polish & Black

| STANDARD | UNS | WERKSTOFF NR. | GOST | BS | OR | EN | JIS | AFNOR |

| Inconel 600 | N06600 | 2.4816 | МНЖМц 28-2,5-1,5 | NA 13 | ЭИ868 | NiCr15Fe | NCF 600 | NC15FE11M |

| Eastern Europe | Aisa | North America | Western Europe | Mid East/Africa |

| Australia | Central/South | UAE | America | Portugal |

| Spain | Indonesia | Italy | Angola | Poland |

| Brazil | Sri Lanka | Russia | China | Singapore |

| Oman | Venezuela | Costa Rica | USA | Qatar |

| Thailand | Canada | Saudi Arabia | Bahrain | Egypt |

| Malaysia | Turkey | Mexico | China | Peru |

| United States | Nigeria | Jordan | Kuwait | Dubai |

| Bangkok | Iran | Germany | UK | New Zealand |

| Vietnam | South Africa | Mexico | Kazakhstan |

| Mumbai | Ahmedabad | Bhopal | Bikaner | Pune |

| Delhi | Chennai | Visakhapatnam | Mangalore | Nagpur |

| Bangalore | Kolkata | Siliguri | Assam | Indore |

| Hyderabad | Surat | Nashik | Cochin | Thane |

| Faridabad | Rajkot | Aurangabad | Bhavnagar | Ranchi |

| Coimbatore | Mysore | Salem | Tirupur | Bikaner |

| Raipur | Bhubaneswar | Bhilai | Ankleshwar | Bhiwandi |

| Vadodra | Kochi |