The company Shasan Piping Solution has been manufacturing 45-degree elbows for a considerable amount of time. This elbow is the next commonly used elbow after the 90-degree elbow. We are receiving the highest caliber products and forming perfect relationships with our customers. We focus on the essentials of our customers while crafting chambers in a variety of lengths, forms, and sizes.

The core component of a piping system used to change the direction of a fluid stream is our pipe elbow. This elbow is used to award the pipe turn in a certain course of 45 degrees or 90 degrees by getting two pipes alongside the equal and non-equal assessments. It serves as a joint between the two pipes, each of which has this right point. This elbow's 45-degree angle, in It appears that a portion of the 90-degree elbow is the field of butt welding steel elbows. There are two types of these elbows: welded and unsurprising. This 45-degree elbow joins with less pressure than the 90-degree elbow. In addition to being attached to lead, steel, copper, plastic, and cast iron, the 45-degree elbow can also be connected to flexible and pure foundations.

Because these 45-degree elbows have so many benefits, they are used in a variety of applications. These benefits include the following: The elbow strengthens and smoothes the interior surface; it uses the least amount of space; it welds a fitting to the pipe, making it completely waterproof; dependable directional shifts reduce pressure disasters and discomfort; and they stop the activity of usage and separation. This elbow exhibits resilience and quick adjustment. 45-Degree Elbow Pipe fittings are categorically taken into account for utilization on mechanical systems, instrumentation, control and cycle frameworks, and substance and oil systems used in liquid power, substance, electronic, squash, and paper plants. The elbow's power source is then featured by redirecting 45-degree elbow pipe fittings.

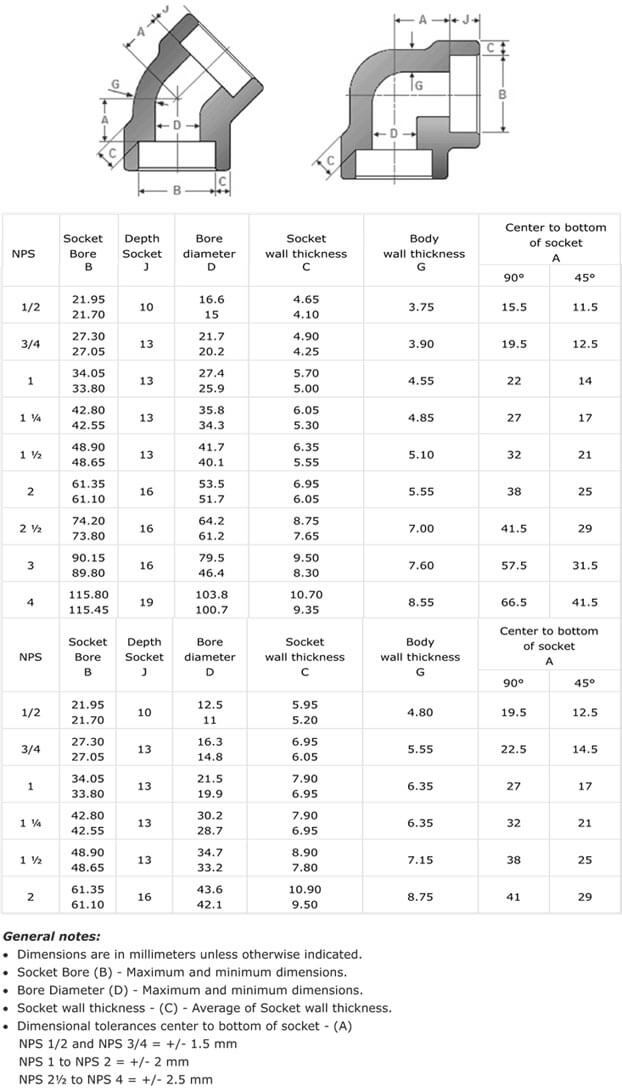

Spread out Steel Socket weld 45 degree elbow does 45 degree revives plainly inside the run of line to make a redirecting game plan. The best method for overseeing partner the line is: work with welding Flanges joints, hung joints and affiliation joints. A SS 45 deg. SW Elbow continually utilized in pipe starting point for the relationship of a line twist. Association weld 45 degree elbow is utilized to Put through two Lines and Cylinders with a relative clear broadness to shape the line turn 45 degrees.

| Specifications | Forged Socket Weld 45 degree elbow |

|---|---|

| Dimension Specification | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| 45 degree elbow Forged Fittings Thread | NPT, BSPT, BSPP |

| 45 degree SW elbow FittingsType | DN15-DN1200 |

| End | Threaded, Welding, JIC |

| 45 degree elbow Fittings Pressure Rating | Threaded end-2000lb/ 3000lb/ 6000lbs 45 degree elbow |

| Connection | Welding |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom 45 degree elbow |

| Size Range | 1/8″ NB TO 4″ NB |

| Manufacturing process | Push, Press, Forge, Cast, etc. |

| 45 degree elbow Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Origin & Mills | Japanese, Indian, USA, Korean, European, Ukraine, Russian |

| Key markets and industries for 45 degree elbow Fittings |

|

| Application |

|

| Carbon Steel 45 Degree Elbow |

|

| Stainless Steel Socket weld 45 Degree Elbow |

|

| Alloy Steel 45 Degree Elbow |

|

| Titanium 45 Degree Elbow |

|

| Inconel 45 Degree Elbow |

|

| Copper 45 Degree Elbow | T1, T2, C10100, C10200, C10300, C10400, C10500, C10700, C10800, C10910,C10920, TP1, TP2, C10930, C11000, C11300, C11400, C11500, C11600, C12000,C12200, C12300, TU1, TU2, C12500, C14200, C14420, C14500, C14510, C14520, C14530, C17200, C19200, C21000, C23000, C26000, C27000, C27400, C28000, C33000, C33200, C37000, C44300, C44400, C44500, C60800, C63020, C68700, C70400, C70600, C70620, C71000, C71500, C71520, C71640, etc |

| Copper Nickel 45 Degree Elbow | Copper Nickel 90/10 (C70600 ), Cupro Nickel 70/30 (C71500), UNS C71640 |

| Brass 45 Degree Elbow | 3602 / 2604 / H59 / H62 / etc. |

| Hastelloy 45 Degree Elbow | Hastelloy C276 (UNS N10276), C22 (UNS N06022), C4, C2000, B2, B3, X |

| Monel 45 Degree Elbow | Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500) |

| Alloy 20 45 Degree Elbow | Carpenter® 20 Alloy, Alloy 20Cb-3 |

| Aluminium 45 Degree Elbow | 5052 /6061/ 6063 / 2017 / 7075 / etc. |

| Nickel 45 Degree Elbow | Nickel 200, Nickel 201 |

| Duplex 45 Degree Elbow | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Super Duplex 45 Degree Elbow | S32750 / S32760 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Incoloy 45 Degree Elbow | Incoloy 800, Incoloy 800H, Incoloy 800HT (UNS N08800), Incoloy 825 (UNS N08825) |

| 254 Smo 45 Degree Elbow | SMO 254/6Mo, UNS S31254, DIN 1.4547 |

| Nimonic 45 Degree Elbow | Nimonic 75, Nimonic 80A, Nimonic 90 |

| Other 45 Degree Elbow material | Tin bronze, Alumunum bronze, Lead bronze |

| Eastern Europe | Aisa | North America | Western Europe | Mid East/Africa |

| Australia | Central/South | UAE | America | Portugal |

| Spain | Indonesia | Italy | Angola | Poland |

| Brazil | Sri Lanka | Russia | China | Singapore |

| Oman | Venezuela | Costa Rica | USA | Qatar |

| Thailand | Canada | Saudi Arabia | Bahrain | Egypt |

| Malaysia | Turkey | Mexico | China | Peru |

| United States | Nigeria | Jordan | Kuwait | Dubai |

| Bangkok | Iran | Germany | UK | New Zealand |

| Vietnam | South Africa | Mexico | Kazakhstan |

| Mumbai | Ahmedabad | Bhopal | Bikaner | Pune |

| Delhi | Chennai | Visakhapatnam | Mangalore | Nagpur |

| Bangalore | Kolkata | Siliguri | Assam | Indore |

| Hyderabad | Surat | Nashik | Cochin | Thane |

| Faridabad | Rajkot | Aurangabad | Bhavnagar | Ranchi |

| Coimbatore | Mysore | Salem | Tirupur | Bikaner |

| Raipur | Bhubaneswar | Bhilai | Ankleshwar | Bhiwandi |

| Vadodra | Kochi |